How to Choose the Right Carbon Steel Coil: Differences Between Hot-Rolled and Cold-Rolled Steel and Their ApplicationsWhen selecting the right carbon steel coil for your project, understanding the distinctions between hot-rolled and cold-rolled processes is crucial. The choice between these two type

A36 steel plate is one of the most widely used carbon steel materials in construction and manufacturing. Defined by the ASTM International A36 standard, this low-carbon steel combines affordability, weldability, and versatility. Its chemical composition includes iron, carbon (up to 0.29%), manganese

What is 4140 Alloy Steel?4140 alloy steel is a versatile and high-performance chromium-molybdenum steel renowned for its exceptional strength, durability, and adaptability across industries. As a medium-carbon steel alloy, it combines precise chemical composition with advanced heat treatment capabil

A36 steel plate is one of the most widely used carbon steel materials in construction and manufacturing. Defined by the ASTM International A36 standard, this low-carbon steel combines affordability, weldability, and versatility. Its chemical composition includes iron, carbon (up to 0.29%), manganese

For generations, engineers and builders have been in pursuit of materials that not only provide structural strength but also stand the test of time against the elements. In this quest, galvanized steel has emerged as a cornerstone in construction and manufacturing industries. From towering skyscrape

When it comes to carbon seamless tubes, choosing the right production process significantly impacts their performance, quality, and application. In this guide, we’ll explore the differences between hot-rolled seamless tubes and cold-rolled seamless pipes, highlighting their unique features, benefits

IntroductionSteel, in its various forms, is an omnipresent material in industrial applications, from construction to manufacturing of consumer goods. Among its different types, carbon steel and regular (mild) steel are frequently compared for their properties and usability in different scenarios. Th

Zhongrun Steel (Foshan) Co., Ltd. is located in the beautiful Foshan City, Guangdong Province. It has 25 years of production and sales experience, exported to more than 30 countries, and has more than 500 cooperative customers. At present, it is an excellent enterprise in the Foshan market in terms

Zhongrun Steel (Foshan) Co., Ltd. is located in the beautiful Foshan City, Guangdong Province. It has 25 years of production and sales experience, exported to more than 30 countries, and has more than 500 cooperative customers. At present, it is an excellent enterprise in the Foshan market in terms

Zhongrun Steel (Foshan) Co., Ltd. is located in the beautiful Foshan City, Guangdong Province. It has 25 years of production and sales experience, exported to more than 30 countries, and has more than 500 cooperative customers. At present, it is an excellent enterprise in the Foshan market in terms

| Availability: | |

|---|---|

| Quantity: | |

DX56D EN

ZHONG RUN

PRODUCT DESCRIPTION

| Product name | DX56D EN GI Sheet |

Technical Standard | ASTM |

Steel Grade | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD |

Type | Sheet/Plate |

Thickness | 0.12~6.00mm |

Width | 600mm-1500mm, according to customer's requirement |

Type of Coating | Hot Dipped Galvanized Steel(HDGI) |

Zinc Coating | 30-275g/m2 |

Surface Treatment | Passivation(C), Oiling(O), Lacquer sealing(L), Phosphating(P), Untreated(U) |

Surface Structure | Normal spangle coating(NS), minimized spangle coating(MS), spangle-free(FS) |

Quality | Approved by SGS,ISO |

ID | 508mm/610mm |

Coil Weight | 3-20 metric ton per coil |

Package | Water proof paper is inner packing,galvanized steel or coated steel sheet is outer packing , side guard plate,then wrapped by seven steel belt.or according to customer's requirement |

Export market | Europe, Africa, Central Asia, Southeast Asia, Middle East, South America, North America, etc |

PRODUCT INTRODUCTION

DX56D Galvanized sheet refers to a steel sheet that has been coated with a layer of zinc on its surface. Galvanizing is a cost-effective and efficient method used for rust prevention, with approximately half of the world's zinc production being utilized for this process.

The purpose of galvanized steel sheet is to protect the surface of the steel sheet from corrosion and extend its service life. A layer of metallic zinc is applied to the surface of the steel sheet, resulting in what is known as a galvanized sheet.

DX56D Galvanized Plate possesses the following general characteristics:

Surface state: Galvanized sheets can have different surface states depending on the treatment methods used during the coating and plating process. These states include ordinary spangle, fine spangle, flat spangle, non-spangle, and phosphating surface. German standards also specify surface grades.

Appearance: Galvanized sheets should have a visually appealing appearance and must not possess any defects that could hinder their usage, such as lack of plating, holes, cracks, excess plating thickness, scratches, chromic acid dirt, white rust, and so on.

In summary, DX56D Galvanized sheet is a steel sheet coated with a layer of zinc, providing excellent corrosion resistance. It offers different surface states and ensures a good appearance without any harmful defects.

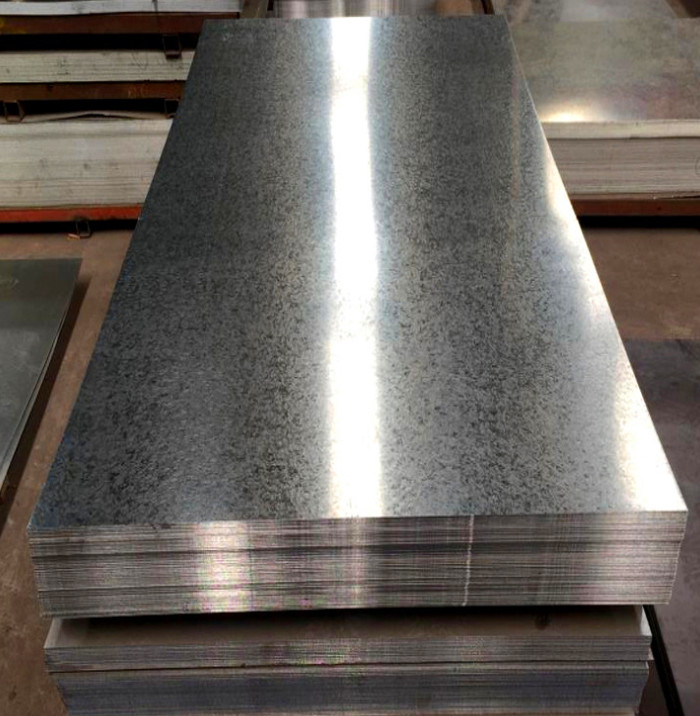

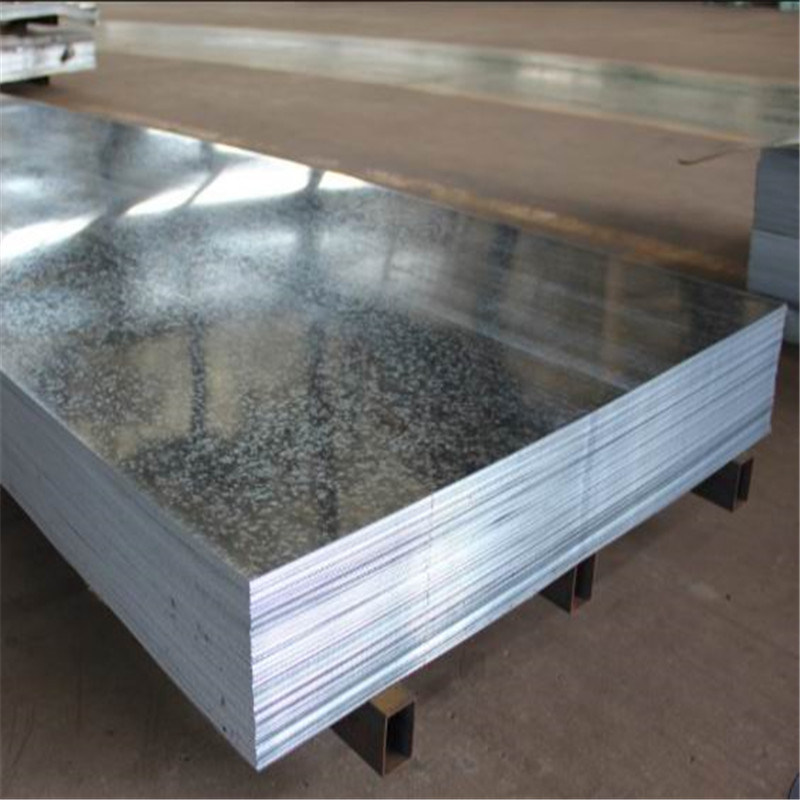

PRODUCT SHOW

|

|

APPLICATION

Galvanized sheet and strip steel products find wide applications in the construction, light industry, automobile, agriculture, animal husbandry, fishery, and commercial sectors. In the construction industry, they play a crucial role in manufacturing anti-corrosion industrial and civil building roof panels, roof grids, and other components. The light industry utilizes them to produce home appliance shells, civil chimneys, kitchen utensils, and more. The automobile industry primarily relies on them for manufacturing corrosion-resistant car parts. In agriculture, animal husbandry, and fishery, they are essential for grain storage and transportation, frozen meat, aquatic products, and other purposes. In the commercial sector, they are used for material storage and transportation, packaging equipment, and more.

These galvanized sheet and strip steel products offer several key advantages:

They possess high strength and excellent deformation ability, along with good adhesion and welding performance.

They exhibit characteristics such as overall rigidity, seismic performance, thermal insulation performance, long service life, spaciousness, short construction periods, and low investment. This series of steel, known for its high strength, is commonly employed in house construction.

They demonstrate strong corrosion resistance, ensuring durability. Additionally, they have a smooth surface and an exquisite appearance, making them suitable for surface building materials or structural parts. They can be used for roofs, walls, waterproof boards, trenches, underground pipes, snorkels, upholstery, fencing, steel frames, and more.