How to Choose the Right Carbon Steel Coil: Differences Between Hot-Rolled and Cold-Rolled Steel and Their ApplicationsWhen selecting the right carbon steel coil for your project, understanding the distinctions between hot-rolled and cold-rolled processes is crucial. The choice between these two type

A36 steel plate is one of the most widely used carbon steel materials in construction and manufacturing. Defined by the ASTM International A36 standard, this low-carbon steel combines affordability, weldability, and versatility. Its chemical composition includes iron, carbon (up to 0.29%), manganese

What is 4140 Alloy Steel?4140 alloy steel is a versatile and high-performance chromium-molybdenum steel renowned for its exceptional strength, durability, and adaptability across industries. As a medium-carbon steel alloy, it combines precise chemical composition with advanced heat treatment capabil

A36 steel plate is one of the most widely used carbon steel materials in construction and manufacturing. Defined by the ASTM International A36 standard, this low-carbon steel combines affordability, weldability, and versatility. Its chemical composition includes iron, carbon (up to 0.29%), manganese

For generations, engineers and builders have been in pursuit of materials that not only provide structural strength but also stand the test of time against the elements. In this quest, galvanized steel has emerged as a cornerstone in construction and manufacturing industries. From towering skyscrape

When it comes to carbon seamless tubes, choosing the right production process significantly impacts their performance, quality, and application. In this guide, we’ll explore the differences between hot-rolled seamless tubes and cold-rolled seamless pipes, highlighting their unique features, benefits

IntroductionSteel, in its various forms, is an omnipresent material in industrial applications, from construction to manufacturing of consumer goods. Among its different types, carbon steel and regular (mild) steel are frequently compared for their properties and usability in different scenarios. Th

Zhongrun Steel (Foshan) Co., Ltd. is located in the beautiful Foshan City, Guangdong Province. It has 25 years of production and sales experience, exported to more than 30 countries, and has more than 500 cooperative customers. At present, it is an excellent enterprise in the Foshan market in terms

Zhongrun Steel (Foshan) Co., Ltd. is located in the beautiful Foshan City, Guangdong Province. It has 25 years of production and sales experience, exported to more than 30 countries, and has more than 500 cooperative customers. At present, it is an excellent enterprise in the Foshan market in terms

Zhongrun Steel (Foshan) Co., Ltd. is located in the beautiful Foshan City, Guangdong Province. It has 25 years of production and sales experience, exported to more than 30 countries, and has more than 500 cooperative customers. At present, it is an excellent enterprise in the Foshan market in terms

| Availability: | |

|---|---|

| Quantity: | |

DX53D

ZHONG RUN

PRODUCT DESCRIPTION

Product Name | DX53D Galvanized Steel Coil |

Wall thickness | 0.12MM~5MM |

Length | 600MM~1500MM |

Standard | BS4449-2005,GB1449.2-2007,JIS G3112-2004, ASTM A615-A615M-04a, Korea StandarsKS D 3504, AustralasianStandard AS/NZS 4671 |

Grade | Q195 Q235 Q345 SGCC SGCH SGC340 SGC400 SGC440 SGC490 SGC570 SGHC SGH340 SGH400 SGH440 SGH490 SGH540 DX51D DX52D DX53D DX54D DX55D DX56D DX57D S220GD S250GD S280GD S320GD S350GD S400GD S500GD S550GD SS230 SS250 SS275 |

Zinc coating | 40g/m2 ~ 275g/m2 |

Coil weight | 1 TON |

Packing | Bundle, or with all kinds of colors PVC or as your requirements |

Surface Treatment | 1. Galvanized 2. PVC,Black and color painting 3. Transparent oil,anti-rust oil 4. According to clients requirement |

Origin | China |

Certificates | SGS ROSH |

Delivery Time | Usually within 10-15days after receipt of advance payment |

PRODUCT INTRODUCTION

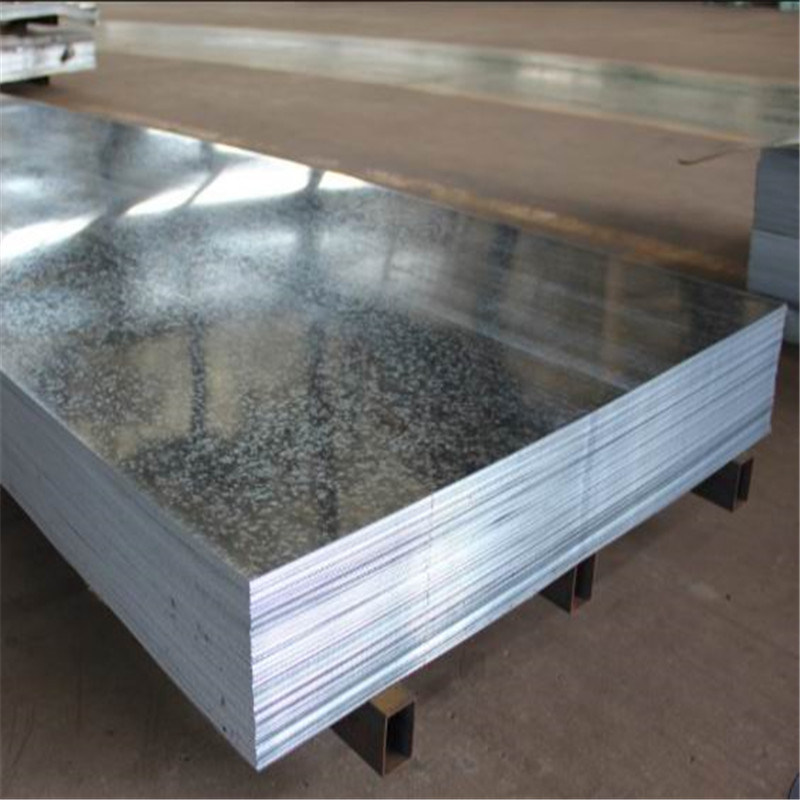

DX53D Galvanized Sheet: Enhanced Corrosion Protection with Zinc Coating

DX53D Galvanized sheet is a steel sheet coated with a layer of zinc on its surface. This cost-effective and efficient galvanizing method is widely used for rust prevention, utilizing a significant portion of the world's zinc production.

The purpose of galvanized steel sheet is to protect the surface from corrosion and extend its service life. It undergoes a process where a layer of metallic zinc is applied, resulting in a galvanized sheet.

The main features of DX53D galvanized sheet include:

Surface Condition: The surface state varies based on treatment methods used during coating and plating, including ordinary spangle, fine spangle, flat spangle, non-spangle, and phosphating surface. German standards also specify surface grades.

Appearance: Galvanized sheets should have an appealing look without defects that may hinder usage, such as lack of plating, holes, cracks, excessive plating thickness, scratches, chromic acid dirt, white rust, and more.

PRODUCT SHOW

|

|

APPLICATION

"DX53D Galvanized sheet and strip steel products have extensive applications in various sectors, including construction, light industry, automobile, agriculture, animal husbandry, fishery, and commercial sectors.

In the construction industry, they are used to manufacture anti-corrosion industrial and civil building roof panels, roof grids, and other components.

The light industry utilizes them for producing home appliance shells, civil chimneys, kitchen utensils, and similar products.

The automobile industry predominantly employs them for manufacturing corrosion-resistant car parts.

In agriculture, animal husbandry, and fishery, they serve purposes such as grain storage and transportation, freezing meat, and aquatic product storage.

Commercial applications include material storage and transportation, packaging equipment, and more.

Key characteristics of these galvanized sheet and strip steel products include:

High strength and excellent deformation ability

Good adhesion and welding performance

Overall rigidity and seismic performance

Thermal insulation performance

Long service life

Spaciousness

Short construction periods

Low investment

They are commonly used in house construction due to their high strength.

Additionally, they offer strong corrosion resistance, ensuring durability. Their smooth surface and exquisite appearance make them suitable for use as surface building materials or structural parts. They can be applied to roofs, walls, waterproof boards, trenches, underground pipes, snorkels, upholstery, fencing, steel frames, and more."